Rope Finishing and Splicing

FINISHINGS of rope – splicing

Because of the complexity of modern materials, a knot decreases the breaking load of the rope at pulling in a significant proportion. Aramids and LCP are hard fibres which do not support much small radii of curves. The Dyneema® fibre is a smooth material and it can be slippery.Therefore, the finishing of the rope is very important. It can vary the breaking load of the rope from 30 to 100% of its linear breaking load. Here are a few examples:

Knot 30-50% minimum of the breaking load

Splice 70 à 90 % minimum of the breaking load

Professional splice 90 % minimum of the breaking load

Linear breaking load 100 % minimum of the breaking load

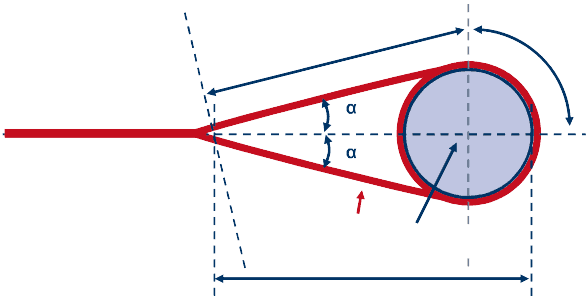

Example of a splice with a Dyneema® braid:

A professional splice is recommended. Several points should be considered.

– Coating: it is recommended to use a Dyneema® braid with polyurethane coating in order to increase interactions at the splice

– Length back in the splice: a minimum length of 80 to 100 times the diameter must be returned in the splice to ensure maximum efficiency

– The Dyneema® returned back into the splice has to be tapered more gradually on a proportional length from 20 to 25% of the returned back length

It is recommended to respect the following geometric system: